70% of food safety alerts in Europe are due to contamination from foreign bodies—an alarming figure that highlights the importance of quality control in the food industry, particularly in the processed meat sector.

Key Facts About Processed Meat and Food Safety

- Over 20% of contamination reports involve the meat and meat-based products sector;

- 1.5 million tons of processed meat are produced annually in Europe;

- 30% of food waste in the industry results from contamination, which could be prevented with more accurate inspections;

- 60% of meat product recalls occur due to undetected foreign objects.

Why Is Advanced Inspection Technology Necessary?

Traditional control techniques, such as metal detectors, are not always capable of detecting non-metallic contaminants like plastic, bone, or glass. In a sector where safety and compliance are paramount, adopting more advanced inspection solutions can make the difference between a safe product and an expensive recall.

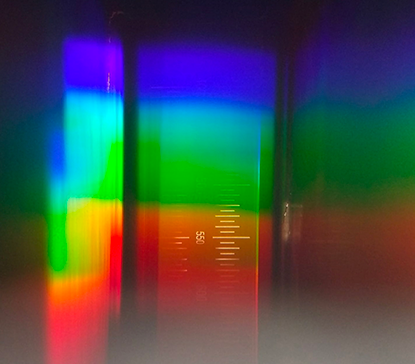

Xnext’s solution: XSpectra

Thanks to XSpectra, its cutting-edge X-ray technology, Xnext —a leading technology partner for food manufacturers worldwide—ensures unparalleled detection accuracy for all types of contaminants, protecting consumers and improving production efficiency. This guarantees:

- Maximum food safety and regulatory compliance

- Waste reduction and minimized financial losses

- More efficient and reliable quality control

XIS4 Top Down XL with XSpectra: The Future of Processed Meat Inspection

The XSpectra system leverages advanced Deep Hyperspectral analysis, comparing up to 1,024 energy levels to distinguish products from potential contaminants with extreme precision. In just a few milliseconds, it performs real-time hyperspectral analysis, detecting impurities that traditional X-ray systems cannot identify.

The XIS4 Top Down XL technology, equipped with XSpectra, represents a major advancement in processed meat inspection, ensuring maximum safety and quality in the production of nuggets, burgers, and patties. Unlike conventional systems, XIS4 Top Down XL detects not only ferrous and non-ferrous metals, glass, and bone fragments but also low-density contaminants such as rubber, plastic, and organic materials—guaranteeing an unprecedented level of quality control in the food industry.

Advantages for the Processed Meat Industry

- Unmatched precision – Detects impurities smaller than those identified by conventional inspection systems;

- Advanced quality control – Identifies foreign materials to ensure compliance with food safety standards;

- Seamless integration – Designed for easy installation in existing production lines;

- Real-time monitoring – Immediate data analysis for efficient production management;

Thanks to its modularity, the system can be customized to meet the specific needs of processed meat manufacturers, offering a versatile and cutting-edge solution.

Meet us at IFFA Frankfurt!

From May 3 to May 8, 2025, we will be at IFFA Frankfurt, the world’s leading trade fair for the meat and alternative proteins industry, held at the Messe Frankfurt exhibition center. This event is a key reference for industry professionals, providing a comprehensive overview of the latest innovations, covering aspects such as processing, preservation, refrigeration, packaging, sales, and food safety of meat products and alternative proteins.

Come and see firsthand how Xnext’s technology can revolutionize quality control in the processed meat sector—visit us at Hall 12, Booth A39!