Xnext, a leading company in hyperspectral X-ray inspection technology with XSpectra, and Turatti, a leading designer of machines and complete lines for fresh fruit and vegetable preparation, have reached an agreement to develop a complete solution combining production and quality control.

The challenge

The inspection systems for the detection of foreign bodies currently used in the production of fresh-cut salads do not allow the identification of a wide set of medium-low density contaminants, especially plastics and rubbers. In addition, the elimination of pesticides and increasingly organic cultivation have led to an increase in cases of organic contamination (sludge, snails, etc.), which are impossible to detect when they are inside the product.

Food companies, increasingly attentive to the aspect of food safety, put at the center of their production strategies the choice of machinery that can ensure it to safeguard the health of all consumers.

The Solution

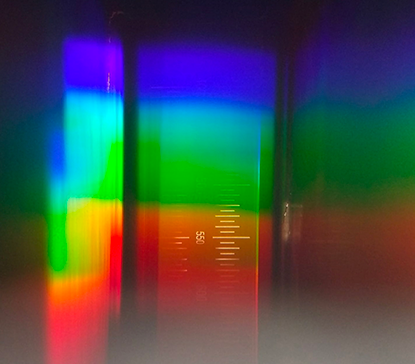

XNEXT®’s state-of-the-art inspection system is able to overcome the limitations of traditional inspection systems, performing real-time hyperspectral analysis to identify low-density foreign bodies such as plastics and lightweight rubbers and organic contaminations, far beyond traditional foreign bodies such as metal, stones and glass.

In addition to significantly improving food safety, XSpectra® reduces the risk of products being recalled from the market and generates a huge amount of data on the inspected product, which is very useful for monitoring and making the production process more efficient.

This technological partnership will allow Xnext® to consolidate the recognized added value that XSpectra® technology can bring to the safety and quality inspection phases and Turatti to expand its industrial offer thanks to the introduction of the best inspection technology for food safety and quality control in the world. By relying on Turatti and Xnext, companies in the fresh-cut sector will be able to have a system that combines Turatti’s experience and XSpectra®’s innovation.

A product is born destined to become a standard within fruit and vegetable processing lines not only to improve production but also to optimize the entire supply chain process, from the raw material to the finished product, minimizing the risk of waste of resources and risks to the health of customers.

This collaboration is an important step in Xnext’s growth strategy because with Turatti we will be able to enhance XSpectra’s innovation and maintain our competitive advantage by offering innovative solutions for our customers as well as for Turatti’s partners.

Bruno Garavelli, CEO Xnext

Thanks to this new partnership with Xnext, Turatti has the opportunity to implement new innovative quality control technologies in our “value proposition” in order to guarantee cutting-edge solutions to our customers.

Turatti strongly believes that in today’s context, the creation of new partnerships is a fundamental pillar to stimulate innovation and improve the service and experience to our customers.

Enrico Gribaudo, CEO Turatti

About Turatti

Turatti is a world leader in the design and manufacture of machines and plants for the processing of fruit and vegetables, providing tailor-made solutions for the fresh food industry. Turatti has been operating on the market for over 150 years: since December 2019 the majority of its shares are held by the Taste of Italy fund managed by Dea Capital Alternative Funds and the EC I fund, managed by Entangled Capital. In 2022, Turatti acquired 100% of the company Tecnoceam S.r.l. based in Collecchio (Pr). Today Turatti is the world leader in plants for the preparation of fresh-cut and pesto and one of the leading suppliers of solutions for fresh-cut products.

About Xnext

Xnext is an innovative SME that has developed XSpectra, a revolutionary non-destructive inspection technology capable of detecting non-conformities in real time in industrial products. In particular, XSpectra contributes to improving the food safety of food by detecting the presence of contaminants such as plastics, bones, cartilage, insects, wood and rubber that would otherwise be undetectable by traditional inspection systems. Xspectra is able to detect such contamination directly on the production line, in a few milliseconds it is able to perform a hyperspectral analysis of the product in real time by comparing the energy absorbed by any contaminants and thus decreeing the compliance or not with the required quality standards.

Xspectra distinguishes itself from traditional inspection systems thanks to the synergy of three technological innovations made by Xnext: photonics, nuclear electronics and Artificial Intelligence. Xnext was the first in the world to harness the power of Deep Learning in the field of X-ray food inspections.

After launching XSpectra on the market in 2022, it now has 55 installations in Italy, France where it has opened a local subsidiary, Slovakia and has acquired orders from Israel, Japan and Germany.